It’s a tradition in print to give your Risograph printer a human name. Risograph printers come alive through the artwork they print & leave little signs behind.

There is pure magic in a little 300lb cube that’s called a Risograph.

These Risograph printers are also called duplicators. Risographs can take on a mind of their own at times and cause happy accidents through the chaos. The ‘happy accidents’ we call them Risograph Quirks or Risograph printing errors. But these are no ordinary print errors and really shouldn’t even be referred to as “errors”, These are quirks that scream “This was printed on a risograph!”.

These Risograph quirks add to the charm of this very unique printing method. They add in random and unpredictable imperfections to the printed work.

Let’s take a look into what can & will happen when printing on a risograph. And what you can expect when Risograph printers decide to leave their mark on your work.

//Disclaimer//

*Not all quirks will happen on every print or print batch*

5th grade reading level: 12 minutes

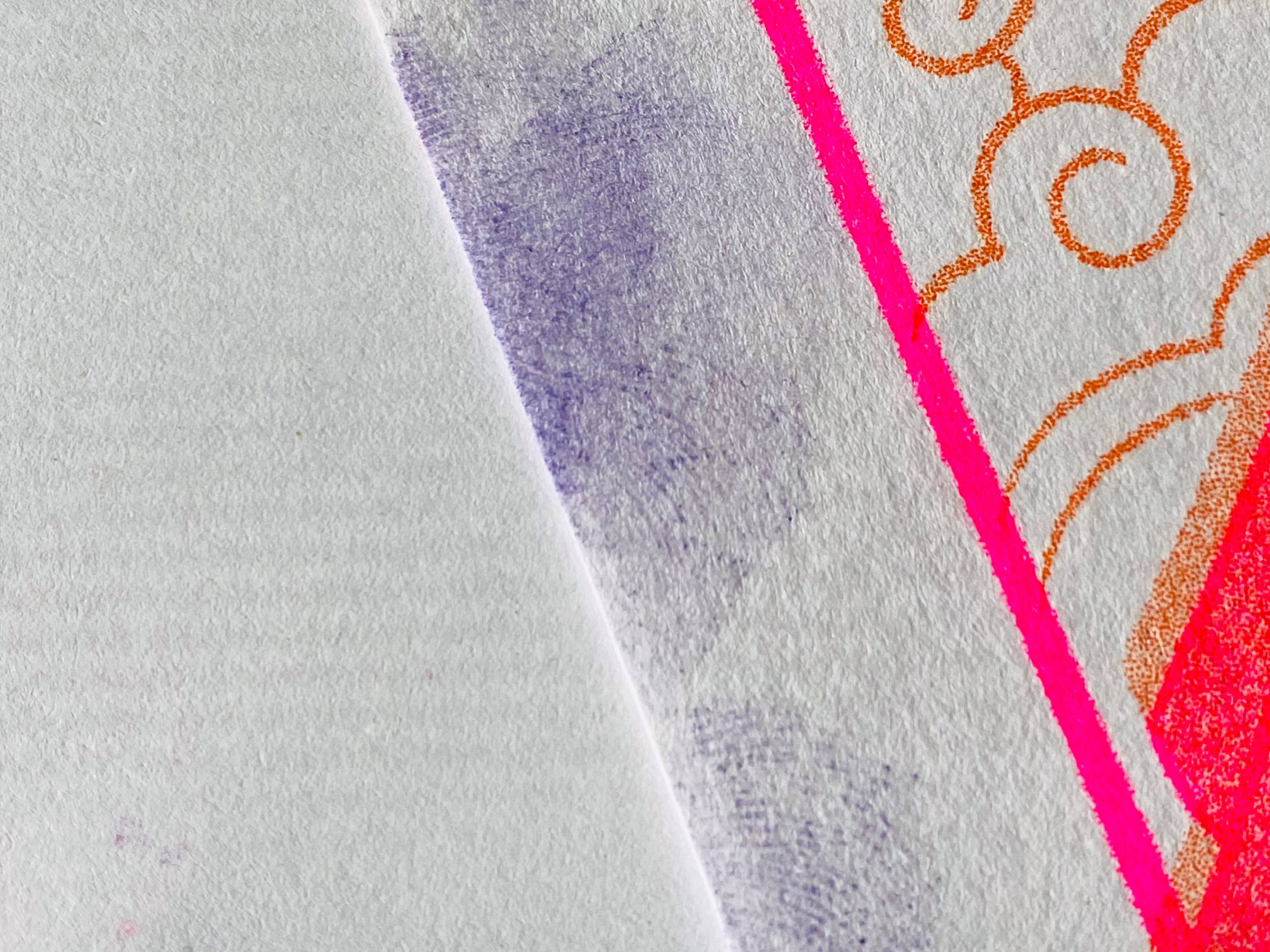

01. Misregistration

Misregistration is the top quirk from these printers you would expect to see. Think of it as either in alignment or out of alignment.

Unlike a traditional office printers, where you can put the paper in & hit print to get your final image. Risograph printers print a single [or up to 2] ink at a given time. Each layer of ink means the paper will go back to the beginning over and over. By doing this per ink layer, the Risograph has a chance to grab the paper a little different each time. Causing slight misregistration in the prints. Misregistration is a quirk you'd want to keep small to not disrupt the image. But it is something that proves the authenticity of these machines. It will happen! The severity of misregistration varies by printer model, or what the moon is up to, the general mood.

This quirk is one we try to keep small, to the best of our luck, but it is not one that ruins the quality of the printed material. So we let it get a pass most of the time.

Example of misregistration between Orange & Fluorescent Pink ink layers

02. Tire Tracks

No, We don’t dry your prints in the road.

Risograph printers use rubber wheels with a tread texture to feed the paper.

These wheels can pick up ink from your print when printing in multiple ink colors. Risographs print with only 1 or 2 colors at a time. The paper will need to go through the printer multiple times throughout a multi-color job. The rubber tires can pick up some of the ink and transfer it to the pages.

This quirk is one that is often easy to solve. You can use a ‘dust free’ eraser to gently erase and remove these marks. But know that a ton of people love seeing them as it’s a sign of the printing process and is 100% unique to these printers.

For art prints, we often don’t mind seeing tire tracks. With something like document printing tire tracks can be a bit distracting. This is definitely a personal preference if you like them on your print or not. Feel free to let us know to leave them or take them away when placing your order!

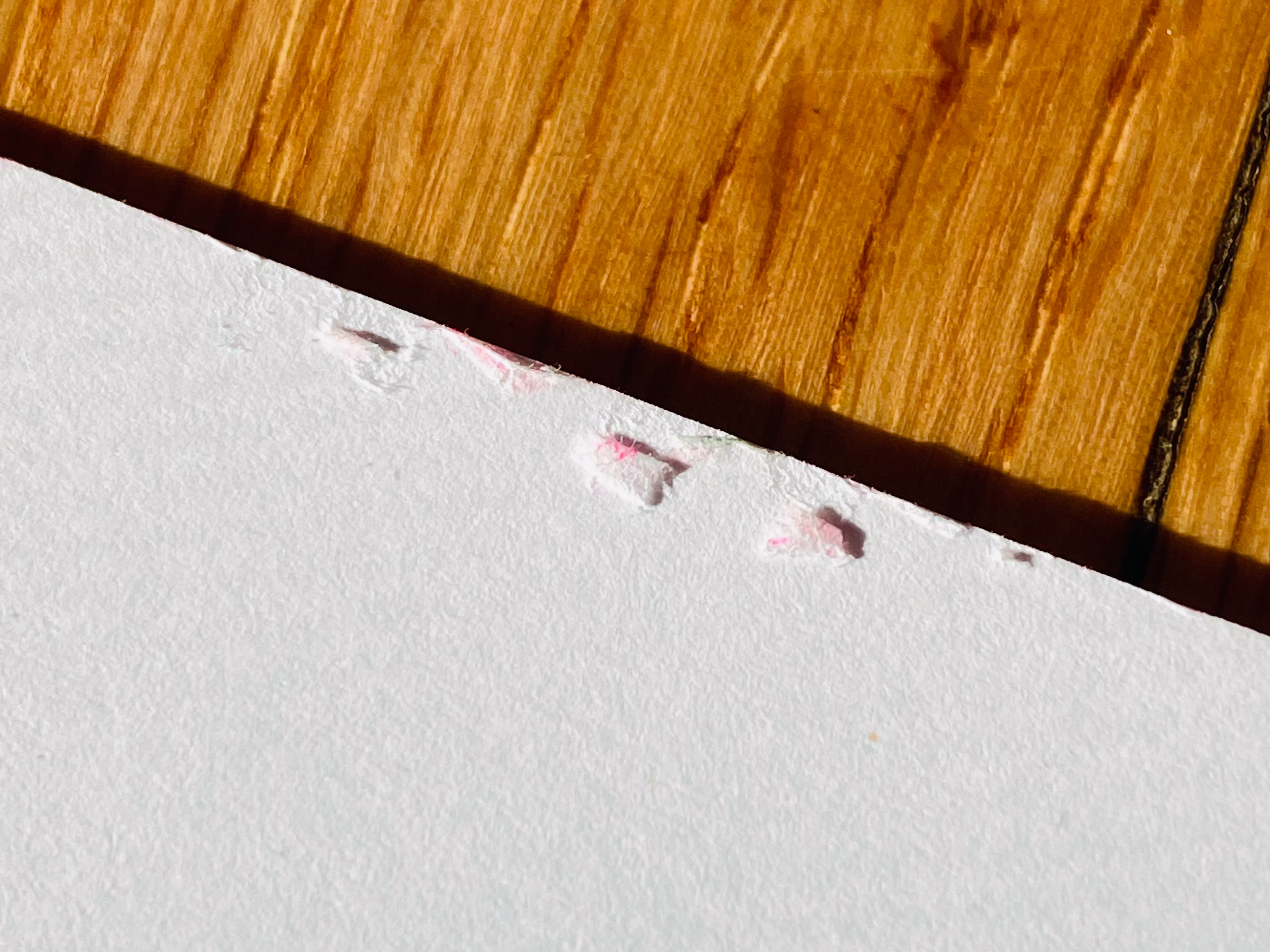

Example of positive tire tracks in red risograph ink

Example of Negative tire tracks along the Fluorescent pink ink area

Image showing the paper feed tires on an mh9450u Risograph printer

03. Smudges

Smudging is one of those quirks that are less desirable. It can either make your print look dirty or ready for the local underground punk show.

Smudges can occur by any means but the source of the issue is always the same. Risograph ink doesn’t “dry”. Well at least it doesn’t dry the same way as everybody is familiar with. These inks use Rice Bran oil [older inks using Soy oil] as a main component in the formulation. Because of this oil base, Risograph inks ‘dry’ through absorption & not evaporation.

This absorption takes some time to happen, from a few days to a few weeks to be somewhat indelible. You should would never get in the habit of rubbing the ink surface of any print let alone a Risograph print. The risk of smudging can happen even if the Riso print is months to years old. The Smudging quirk can happen while printing, but often only happens after completion. To avoid the risk of smudges along the edge try designing with a white border. You can also use poly bags, minimal handling, or spray fixative to protect the print.

You can remove ink smudges with a dust free eraser.

Example of an ink smudge on a risograph zine where the image was smudged downwards.

04. Finger Prints

Get out your best detective costume & magnifying glass!

Like smudges but proof a human did it and not some tiny print ruining cryptid. These are cause by, you guessed it, FINGERS! To keep customers at markets from causing finger prints, design with a white border or put the print in a poly bag.

For books and zines make sure you get some good dry time before debuting your product. You can also try a spray fixative on the covers.

Reframe: You could skip all that extra design work & protection. Think of it as the more you read the more the book changes showing signs of patina like a good leather jacket.

Remove any rouge fingerprints from a risograph print with a dust free eraser!

Example of fingerprints in Purple risograph ink on the side of an art print

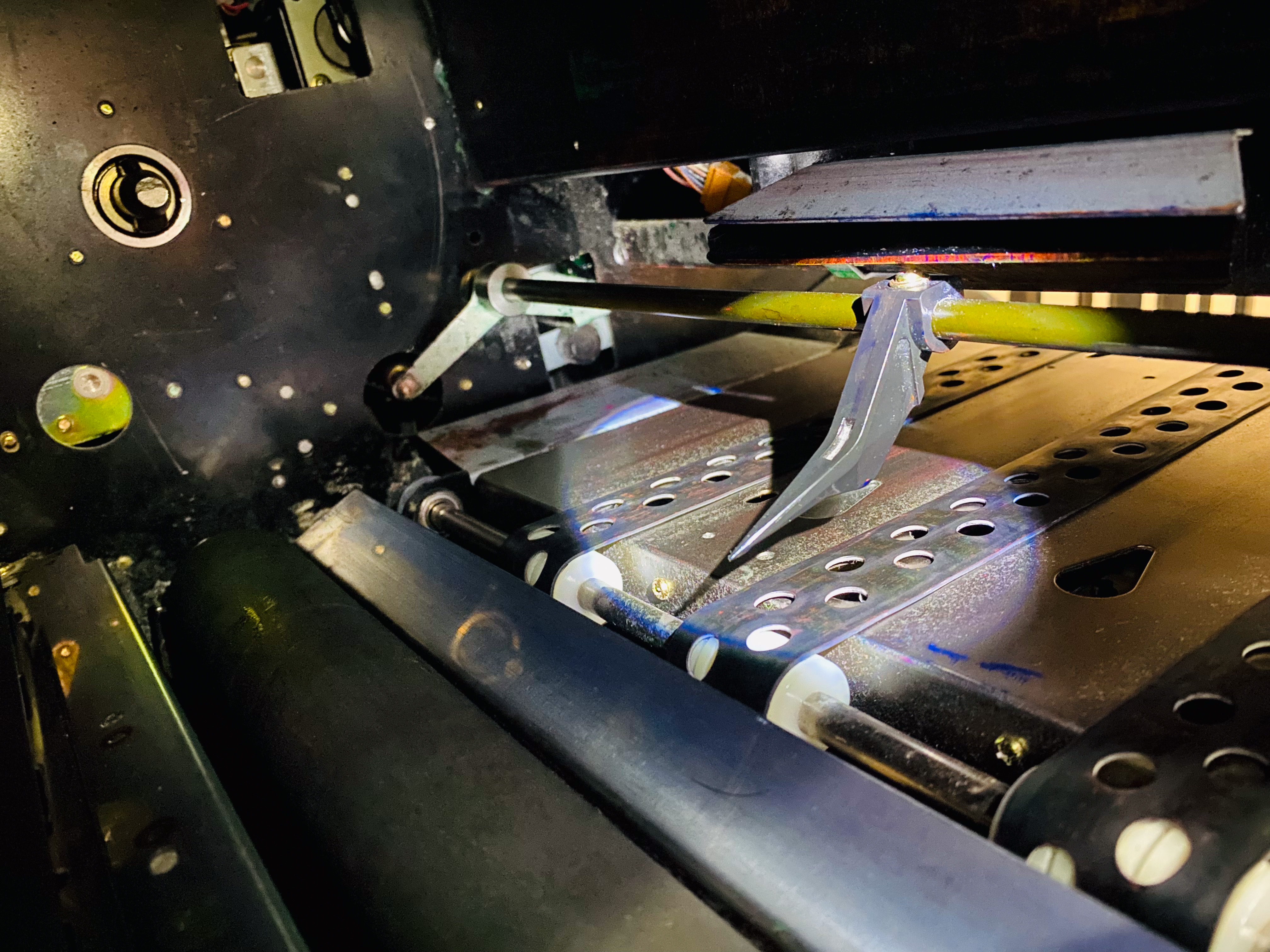

05. Needle Strike

Like a tattoo artist who sneezed while tattooing your mom’s new boyfriend’s name on your arm.

Needle strike is a mark made from a piece of the internal mechanism of a Risograph printer. During the printing process, the paper starts in the feed tray. The paper then goes to the ink drum, called a “color drum” where the printing happens. The paper slightly sticks to this color drum to print. A then needle moves in at the correct time to remove this paper in a flicking motion. The paper removing needle can scrape some ink off the print and draw a line down the sheet of paper.

Needle strike is fairly rare and only happens when the paper has a bit too much ink on it. The over inking causes the paper to stick to the color drum more than normal.

This quirk is often pulled from the final batch as it doesn’t have a desirable or attractive look.

Example of needle strike down the center of a test print in Black Riso ink

Image showing the paper removal needle on an rc6300 Risograph [Frank] highlighted with a flashlight

06. Grain

The one grain you can’t go against.

Grain is a big piece of what makes a the product identifiable as a real Risograph print. The distinctive Risograph Grain pattern used to print is unique to these printers. This pattern is a special type of Dither pattern, but we won’t get into all the technical aspects of how cool it is here.

This "quirk" is what defines the risograph process. It is what makes it desirable, what makes it cool, and what makes it authentic. The Risograph grain pattern can be seen more evident through ‘transparency’ of the ink. As it interprets transparency through dots or density rather than opacity. The closer the dots the darker the area, the more sparse the dots, the lighter the area would be.

Examples of this density dot pattern is in our risograph color books.

This quirk isn’t something to fix, remove, or hide. Only cherish and revel it it’s effect.

Three examples of risograph grain

07. Uneven Coverage

Uneven coverage is a Risograph quirk that has mixed reactions. It can show the authenticity of the printing process. But it also can leave a heavily textured area that doesn’t include the entirety of the image. It is a delicate balance between a cool print and a failed print.

Uneven Risograph ink coverage can range in severity. Ranging from nonexistent to pretty obvious. Dry or cogged ink color drums causes the majority of uneven coverage in a Risograph print.

Stopping to clean the printer and reprinting can solve the uneven coverage for most. Another way uneven coverage can happen is the wont paper can’t take any more ink. The desire would need to rework the file to allow for less ink density of the page.

Uneven coverage can also be a quirk of the individual Risograph itself! The color drum of choice & the printer can react to each other to cause weird things to happen. The older the Risograph machine is the likelihood of a “proprietary” defect is high.

On our Risograph from 1992 named Frank, some color drums we have are not as even coating as others. This type of uneven coverage is part of the charm and can only be avoided by retirement of that equipment. & that's not going to happen anytime soon for Frank.

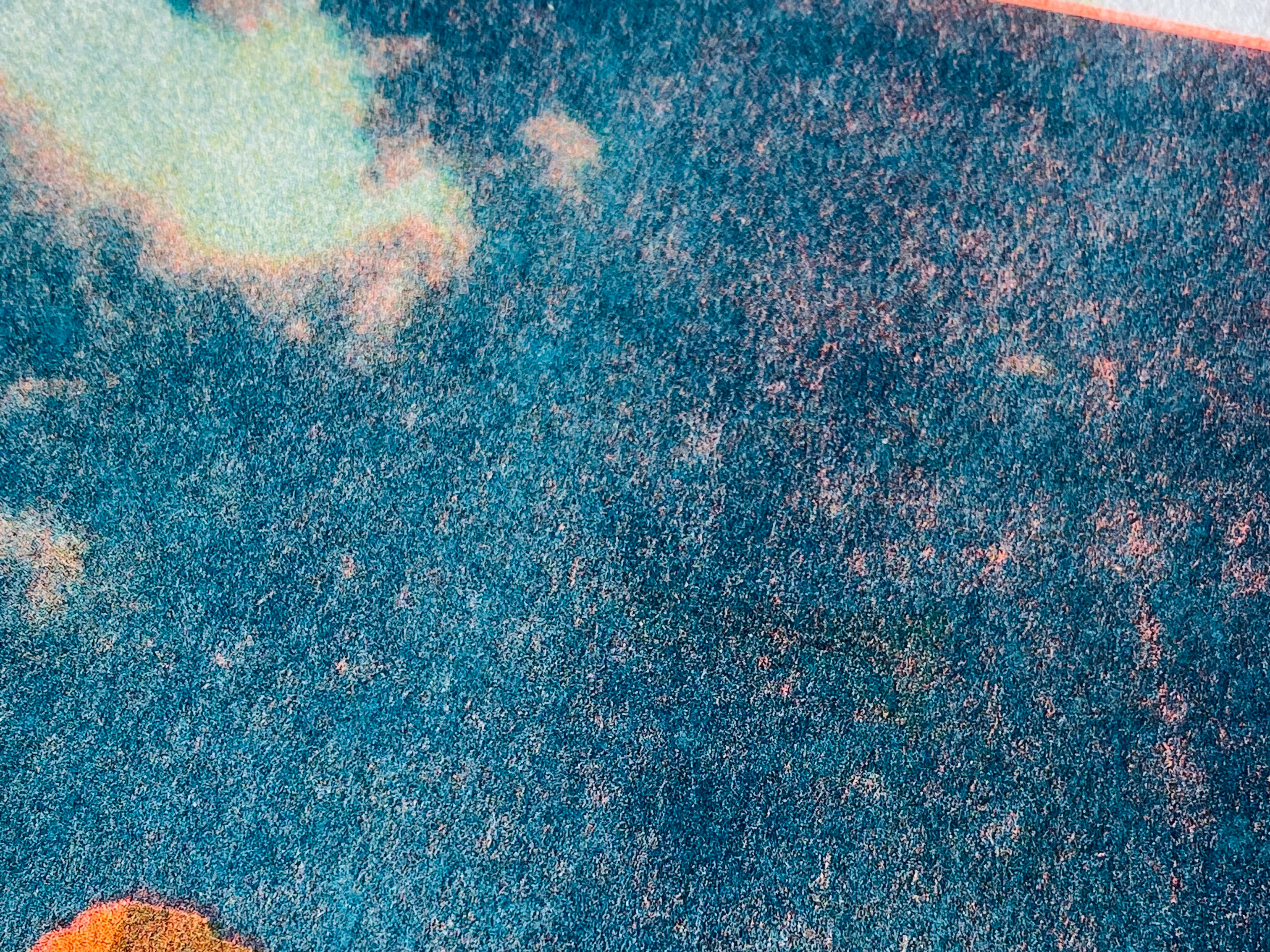

Example of uneven risograph ink coverage with Teal ink over Fluorescent Orange and Yellow inks

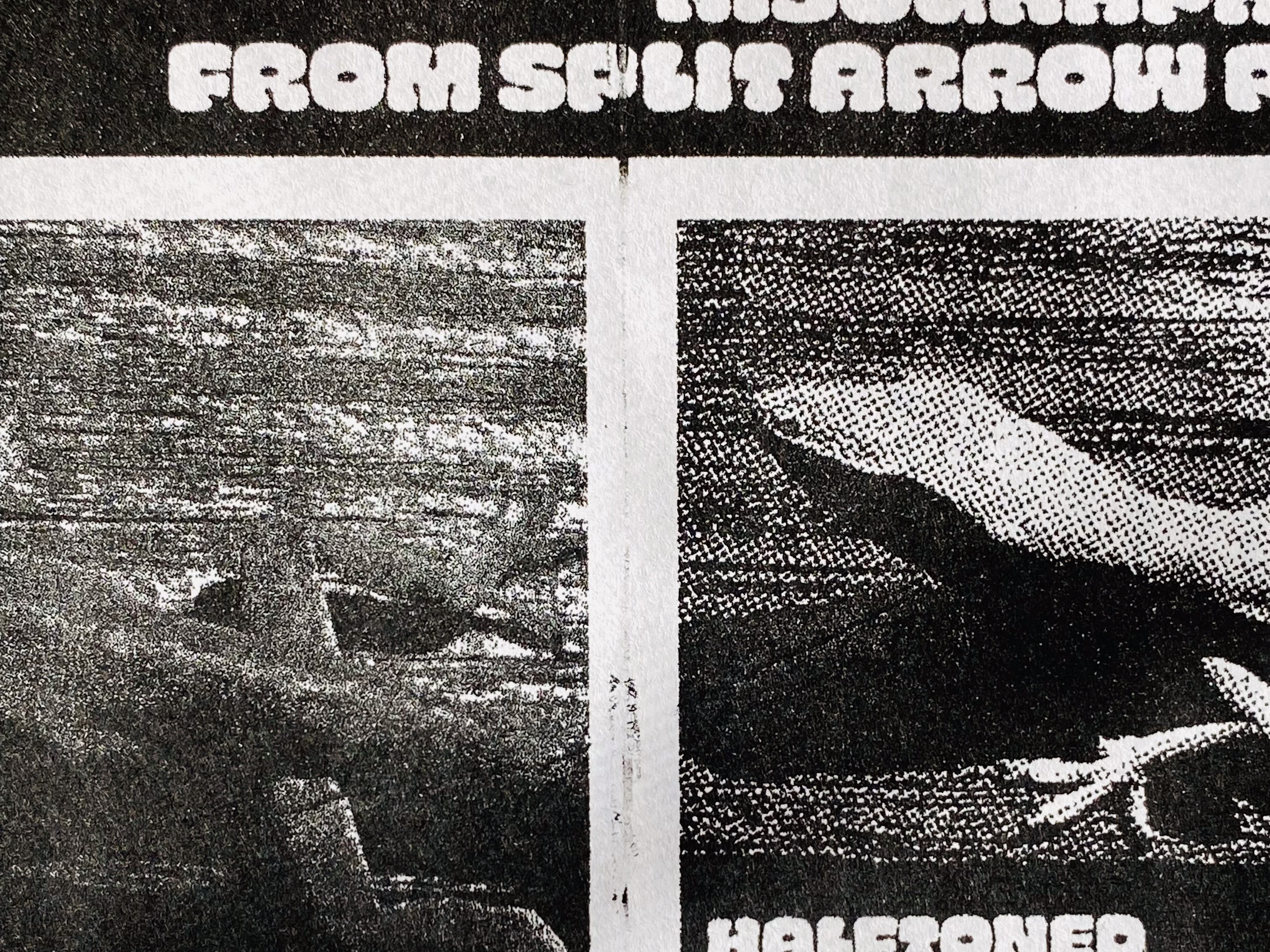

08. Dot Gain

Dot gain is a quirk all printers on the planet have. Dot gain is a measurement and appearance of how much did the ink spread when it touched the paper. The dot gain effect is often taken advantage of when printing on an inkjet printer. It is used to smooth out the color transitions between colors. On a printer that prints clear and obvious “Dots” like a Risograph, this dot gain can sometimes be disruptive.

Too much dot gain can be distracting or even limiting. How much detail gets shown when working with small type or fine details is defined by the dot gain.

We’ve noticed that our inventory of Soy based inks have a touch more gain than the newer Rice based inks. For most this isn’t an issue you would ever notice, or one to worry about.

If you want to check out how much the ink will spread, check out our risograph color books to see them in person!

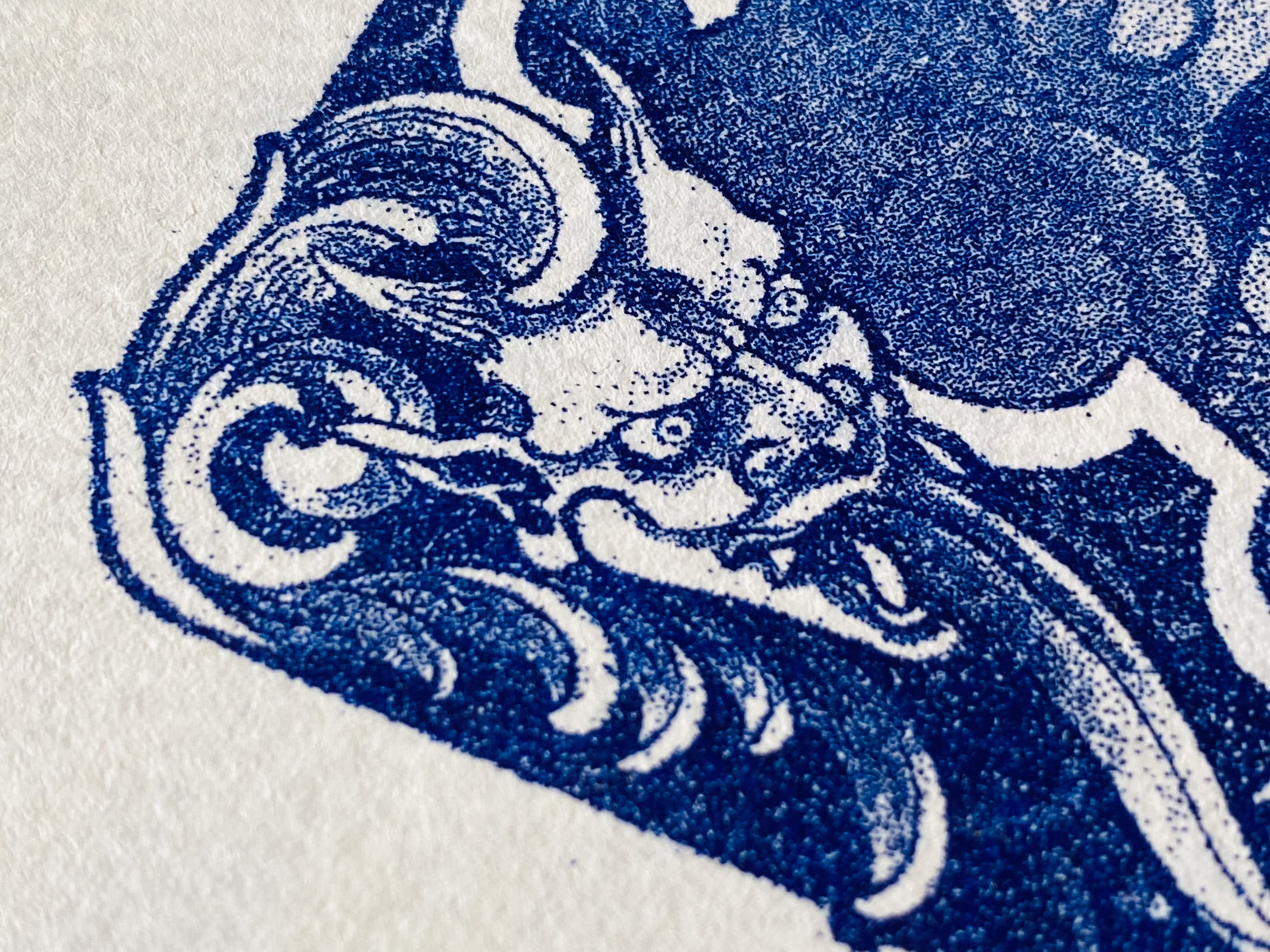

Example of close up risographs dots in Medium Blue ink

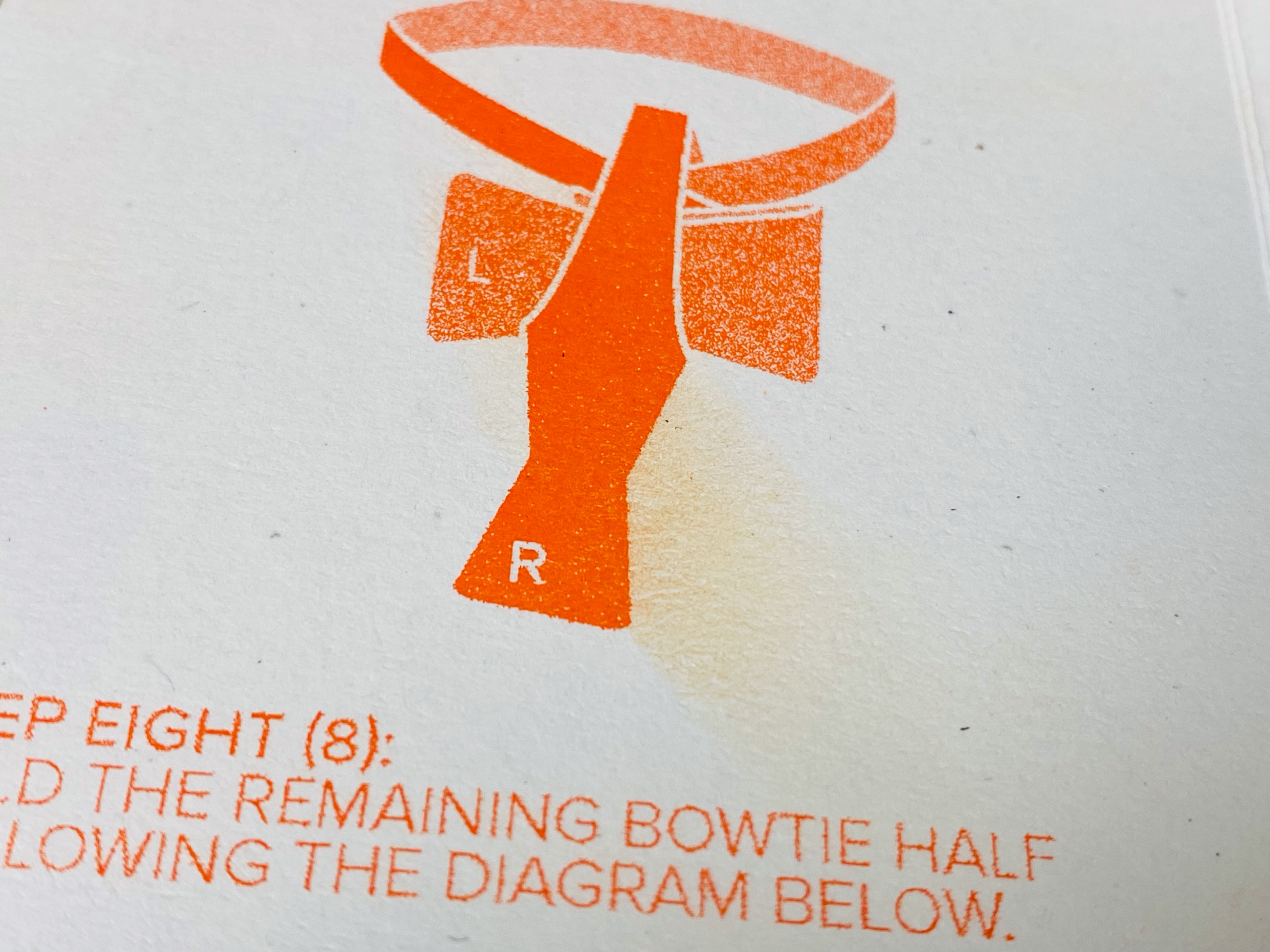

09. Bow Ties

Bet this one isn’t on the list from our AI robot overlords.

Bowties are a quirk we try to remove on customer work to the best of our ability. But often include them our personal work if it’s not too distracting to the final art piece.

Like a skid mark on the road, the rubber wheels that feed the paper pause on one spot scuffing the ink & paper. The paper staying still while the feeding wheels move cause a bowtie shape to appear.

These bowties are often in the center in the top 1/3rd of the page but can occur anywhere in the center line of the paper. This position makes them near impossible to remove from the print. Unlike fingerprints, Tire tracks , or smudges, bowties are less isolated.

The bowtie mark is often right in the middle of the design and removing it would damage the artwork. When bowties occur we pull them from the batch when it's severe enough to disrupt the image. Bowties happen randomly and coincide with paper jams.

They happen, we just remove the print when we can!

Example of a Risograph bowtie in green ink

10. Paper Jam

Risograph printers jam, and they jam often and can in many ways. Risograph printers need a specific environment & conditions to print well. Including but not limited to:

- Paper grain direction

- Humidity

- Temperature

- The file’s ink density

- Paper thickness

- Paper types

- Age of the equipment

- Ink type & age

- Synchronization of a ton of mechanical pieces and belts

- Luck

Most of the time too much ink in the leading edge of the paper causes the paper to stick to the color drum causing a jam. We made templates to help make sure your file is printable and highlight the jam zone for you!

Reworking a file that jams often is sometimes needed. By lightening the density of the artwork by even 10% or by using a larger sheet of paper when possible can solve jams.

Paper jams often can lead to redesign but never make it to the final printed project. [because it can’t print]

Example of a paper jam [screen shot from a video]

11. Top Edge Peel

This quirk isn’t a big deal for art prints since majority are one sided and are heading into a frame. But this quirk can be troublesome for 2 sided printing.

Printing with paper that is thick or goes against the paper grain it's common to see this quirk. The tires that cause tire marks can scuff the paper severely on the back side and peel the leading edge back.

You can avoid Top Edge Peel sometimes by adjusting the pressure of the paper feed tires on the printer. With older models this sometimes change of pressure isn’t as possible.

Top edge peel can sometimes happen even if everything was set up perfectly. We have seen this happen in the middle of a print job where only one or 2 prints have this happen in a batch of 25. At times it’s random and how the Risograph reacted to that specific sheet of paper.

This Risograph quirk doesn’t affect the artwork unless it has 2 sides. Lighter weight papers do not have this issue. Mostly 80# or heavier papers run this risk.

Top edge peel can be removed from a Risograph print. Gently erase with a dust free eraser and it should come right off the print without further damage. Some rough texture may still be present.

Example of top edge peel caused by the risograph paper feed tires on the back of a print

12. Ghost Images

The Riso ghosts blessed you in a 2 for 1 print!

A ghost image is when ink is picked up and put back down where it doesn’t belong on the same sheet of paper.

Few things cause a Ghost Image to appear. As we know Risographs have a mind of their own sometimes. The printer can grab the paper and send it out of the proper sequence, misfeeding the paper. This misfeed can transfer ink onto the color drum where it's not supposed to be. The ink transfer is what gets put back down over and over across the printed image causing a ghost to show up.

Ghosts can also appear when a print transfers to another causing a mirrored image. This is rare and preventable by making sure everything is right side up!

Prints with ghost images will be removed from the batch. The interior of the printer is then cleaned and the job starts again without the ghost image.

Example of a ghost image on an envelope where the delivery line are duplicated across the print

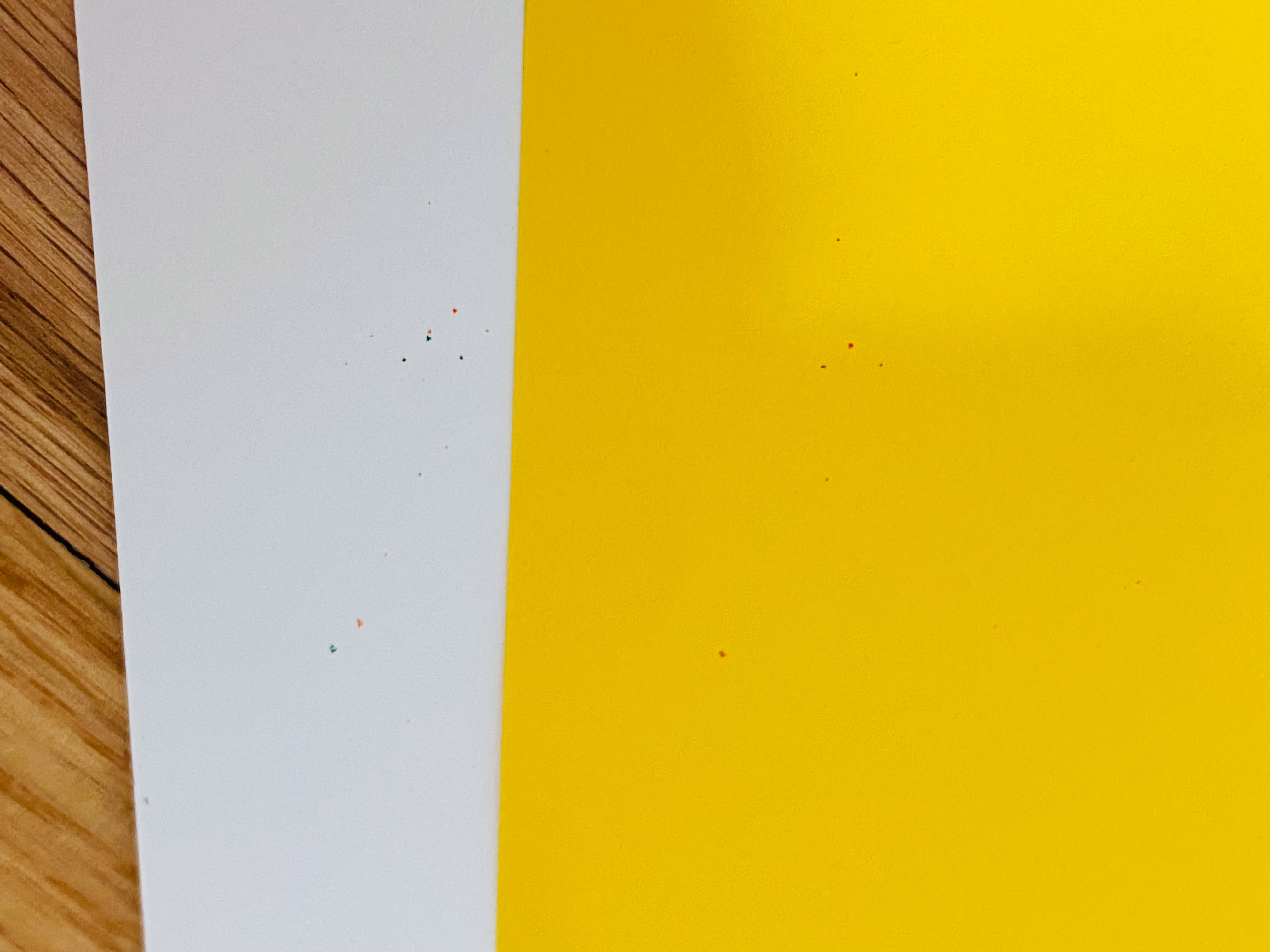

13. Ink Transfer [set-off]

Like a ghost image but more smudgy. Ink transfer will be on the back of the printed paper.

The Risograph ink transfer quirk is from wet ink touching the back of the next print in the paper trays. This quirk is often not of consequence if your work ends up in a frame, but if it’s a 2 sided print it can be a bit troublesome.

To solve this quirk you need more time between each print to allow for some ink absorbency. You an also add sheets of glassine or blank paper between prints to blot this ink up. [slip sheet sorting / blotter paper]

We don’t really mind this quirk for art prints. We won't actively remove it as we find an it inevitable part of printing with Risograph ink. But for documents, books, or zines we make sure this doesn’t occur to a severity that disrupts the next pages.

By using a dust free eraser you can remove any ink transfer by gently erasing it away!

Example of ink transfer on the back of an art print in Orange and Green risograph ink

14. Beauty Marks

Beauty marks are one of our favorite things about risograph quirks. They are extraordinarily rare and mostly come from older Risographs. Our Riso from 1992 is an RC6300 model name Frank. This printer has been rebuilt and refurbished in house. Part of what makes his impressions unique are the Beauty Marks.

Caused by corrosion in the thermal imager & stage glass area. Frank leaves a series of dots on every impression he creates in the same locations every time. This isn’t planned or something we can fix. We can remove the beauty marks by blocking out the dots with tape, but choose not to.

This quirk is something we find really cool and is a sign that it came from a printer that's 30 years old. Frank the printer should have been decommissioned in the early 2000's. He has been with us since 2016 and we embrace these marks. We see them as part of a collective biography that we all take part in, and should be proud of!

Example of Risograph Beauty Marks on two prints with 3 different inks. you can see a triangle shape and lower an individual dot present on all prints from Frank the risograph [our rc6300 from 1992]

Risograph quirks are something that is part of an authentic printing process.

Zero of these quirks should be scary to you when ordering Riso printed products. But instead reframed as quirks of a unique printing method you should embrace.

There is beauty in letting go control and allowing a machine to be a co-creater in your work. There is no substitute for a true Risograph created image quirks in all. Allowing variance in your printed goods will attract interest & give you a story to tell. You should be proud to share and talk about how your art was printed.

We love seeing this printing process take off and get more popular! We are excited to share the quirks you can expect to see in your own Risograph printed projects.

Check out our riso care kit to learn more about taking care of your riso prints!

This was written without the use of AI and was typed by a real human!